In the wave of green transformation in the global manufacturing industry, controlling volatile organic compound (VOC) emissions has become a mandatory requirement across various sectors. From automotive interiors to furniture manufacturing, from textile lamination to electronic product assembly, traditional solvent-based adhesives are gradually being replaced by more environmentally friendly alternatives. In this quiet "de-solventization" revolution, polyurethane reactive hot melt adhesives are standing out due to their exceptional environmental characteristics and stable performance, emerging as a key technological force driving low-VOC, eco-friendly production.

VOCs are organic chemical substances that easily evaporate at room temperature, commonly found in solvent-based adhesives, paints, and cleaning agents. In industrial production, they are not only significant precursors to photochemical smog and PM2.5 but also pose direct health risks to frontline workers, potentially causing respiratory irritation, headaches, and even long-term damage. As global environmental regulations become increasingly stringent (such as China’s "14th Five-Year Plan" VOC Comprehensive Management Initiative and the EU’s REACH regulations) and end consumers show a growing preference for "green products," reducing VOC emissions during production has shifted from an environmental choice to a necessity for market access, brand reputation, and sustainable development.

Traditional solvent-based adhesives or some early-generation hot melt adhesives inevitably release VOCs during application and curing. Finding a bonding solution that meets stringent performance requirements while fundamentally and significantly reducing VOCs has become a common demand in the manufacturing industry.

The core innovation of PUR adhesive technology lies in its unique "water-based dispersion" system. It stabilizes polyurethane resin in the form of tiny particles dispersed in water, rather than dissolved in organic solvents.

The Eco-Friendly Nature of Near-Zero VOC Emissions: During the production and application of PUR adhesives, the primary substance volatilized is water vapor. Their formulations contain almost no or only trace amounts of organic solvents, eliminating the vast majority of VOC emissions at the source. This enables factories using PUR adhesives to easily meet the strictest indoor air quality and environmental emission standards without investing in expensive end-of-pipe exhaust treatment equipment, significantly reducing compliance costs.

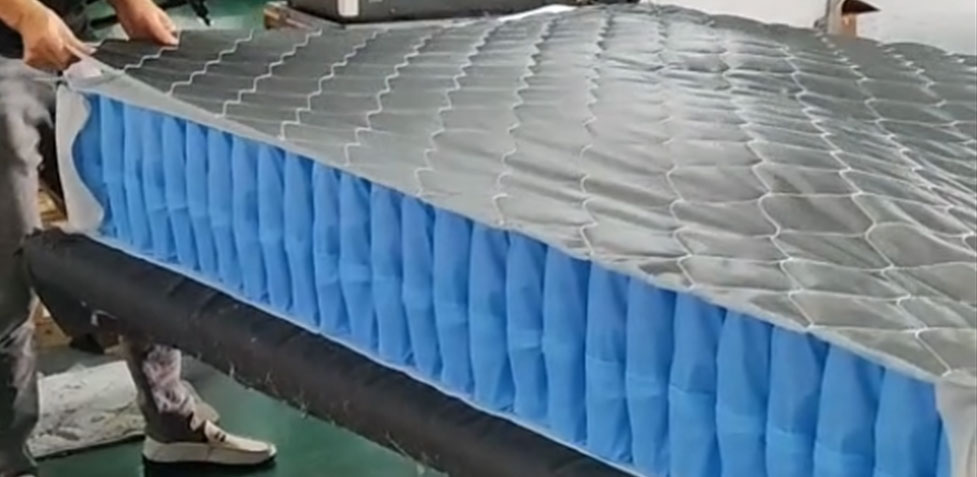

Performance Without Compromise: Balancing Environmental Friendliness and Strength: Many hold the misconception that "eco-friendly equals weaker performance," but PUR adhesives completely break this stereotype. After water evaporates, the reactive groups they contain undergo cross-linking reactions with moisture in the air or substrates, forming a thermosetting adhesive film with a three-dimensional network structure. This gives them high final bonding strength, excellent heat resistance, solvent resistance, and creep resistance. Their performance is comparable to, or even surpasses, many solvent-based products, making them particularly suitable for applications requiring high durability, such as automotive interior bonding, footwear material lamination, and high-end furniture edge banding.

User-Friendly Application and High Efficiency: PUR adhesives offer good storage stability and can typically be applied using conventional spraying, roller coating, or blade coating equipment. Cleaning requires only water, greatly simplifying operational processes and reducing maintenance costs. Their open time and curing speed can be flexibly adjusted through formulations to meet various needs, from manual operations to high-speed automated production lines.

The environmental advantages of PUR adhesives are being translated into tangible productivity and competitiveness across multiple industries:

Automotive Interiors and Filter Manufacturing: The interior of a vehicle is an enclosed space with extremely stringent requirements for VOCs and odors. PUR adhesives are widely used in the lamination of dashboard panels, door panels, headliners, and other interior materials, as well as in the production of automotive air conditioning filters. They provide strong bonding while ensuring compliance with VOC standards for entire vehicles, enhancing driving health and comfort.

Furniture and Building Materials Industry: In applications such as furniture board edge banding, wood veneer lamination, and decorative material lamination, PUR adhesives help factories establish truly "green production lines," producing products that meet E0-level environmental standards or earn "green building material" certifications, catering to high-end markets and export demands.

Textile, Footwear, and Apparel Industry: In processes such as sports shoe fabric lamination and functional garment bonding, PUR adhesives provide soft, breathable, and wash-resistant bonding effects. Their production process is free of irritating odors, improving factory environments and aligning with the strict environmental standards of international brands’ supply chains.

For manufacturing enterprises, adopting PUR adhesives is not just about compliance with regulations but also a strategic investment for the future.

1. Enhancing Product Value and Market Competitiveness: "Green products" manufactured using eco-friendly materials are more likely to gain consumer favor and meet the supply chain audit requirements of large buyers (such as well-known automotive brands and home furnishings retailers), thereby opening doors to broader markets.

2. Achieving Sustainable Development (ESG) Goals: Reducing VOC emissions is a key initiative for companies to fulfill their environmental responsibilities and build a responsible brand image. This directly contributes to their environmental, social, and governance (ESG) performance and attracts green investment.

3. Optimizing Production Environments and Costs: Improving workshop air quality safeguards employee health while reducing potential risks and costs related to environmental management and workplace safety.

PUR adhesives, with their ingenious chemical wisdom of "replacing oil with water," are reshaping the environmental boundaries of industrial bonding. They represent a cleaner, more responsible production philosophy: pursuing performance without compromising the environment or health. As technology continues to mature and costs become increasingly optimized, PUR adhesives are poised to evolve from a current "advantageous solution" into the standard configuration for low-VOC, eco-friendly production in the future.

For manufacturers determined to lead the green transformation of their industries, deeply understanding and actively applying PUR adhesive technology is not just about choosing an adhesive but about choosing a healthier, more sustainable future.

About Sinohesive

As a leading Chinese expert in the research, development, and manufacturing of polyurethane reactive hot melt adhesives (PUR), Sinohesive remains committed to advancing green manufacturing through material innovation. Our Water-Based PUR Series embodies this commitment. We provide high-performance, low-VOC, eco-friendly bonding solutions for customers in furniture, automotive, textile, packaging, and other industries, empowering them to easily meet environmental regulations and enhance their products' green competitiveness. Choosing Sinohesive PUR means choosing a dual commitment to exceptional quality and the future of our planet.