In mattress manufacturing, adhesives play a critical role in determining structural stability, product durability, comfort, and long-term performance. As the industry continues to upgrade toward higher quality standards and automated production, many manufacturers are reassessing a key question:

Should mattress production continue using traditional adhesives, or transition to PUR adhesives?

This article provides a practical comparison between PUR adhesives and traditional mattress glues, helping manufacturers make informed bonding decisions.

Throughout their service life, mattresses are exposed to:

Continuous compression and recovery cycles

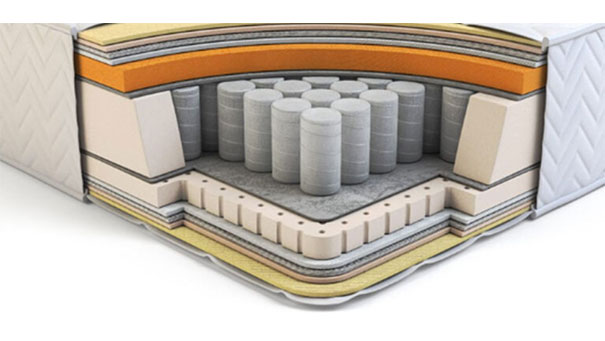

Bonding of multiple materials such as foam, nonwovens, fabrics, and support layers

Strict requirements for low odor and product safety

Long-term performance stability under different environmental conditions

Therefore, mattress adhesives must deliver a balance of strength, flexibility, durability, and environmental resistance.

Common traditional adhesives used in mattress production include solvent-based adhesives, water-based adhesives, and conventional hot melt adhesives.

Lower initial material cost

Familiar processing methods

Fast initial bonding in simple applications

Limited long-term fatigue resistance

Performance degradation under temperature and humidity changes

Odor and environmental concerns in some systems

Less stability in high-speed automated production

As mattress lifespan expectations increase, these limitations become more apparent.

PUR adhesives (polyurethane reactive adhesives) offer a dual bonding mechanism—fast initial set followed by moisture-curing chemical crosslinking—providing several key advantages.

Once fully cured, PUR adhesives form a cross-linked network that maintains bond integrity under long-term compression and cyclic loading, making them ideal for load-bearing mattress structures.

Compared with traditional glues, PUR adhesives maintain bonding strength after repeated compression cycles, helping extend mattress service life.

PUR adhesives exhibit strong resistance to humidity and temperature variation after curing, reducing the risk of bonding failure in different climates and usage conditions.

PUR adhesives offer:

Fast initial tack for continuous assembly

Controllable open time for process flexibility

Stable flow behavior for automated spraying and dispensing systems

These features make PUR adhesives well suited for modern mattress production lines.

| Comparison Factor | Traditional Glues | PUR Adhesives |

|---|---|---|

| Initial Cost | Lower | Higher |

| Long-Term Stability | Moderate | Excellent |

| Fatigue Resistance | Limited | Excellent |

| Environmental Resistance | Moderate | High |

| Automation Compatibility | Moderate | High |

| Support for Long Product Life | Limited | Strong |

From a total lifecycle perspective, PUR adhesives provide higher long-term value despite higher initial material cost.

In practical decision-making:

Traditional adhesives may still be suitable for low-end or short-lifecycle products

PUR adhesives are recommended for premium mattresses, long warranty products, and automated production lines

PUR systems are especially advantageous for multi-material and complex mattress structures

Adhesive selection should be evaluated based on product lifecycle performance, not only material cost.

As mattress manufacturing shifts from cost-driven competition to quality- and experience-driven differentiation, adhesive selection has become a strategic decision. PUR adhesives provide superior durability, fatigue resistance, and production stability, making them an increasingly important solution for modern mattress manufacturing.

Sino Adhesive specializes in the development and production of PUR adhesives and polyurethane reactive adhesive systems, serving mattress manufacturing, furniture, woodworking, textiles, and composite material industries. The company provides stable bonding solutions and professional technical support tailored to different materials and production processes.