In modern manufacturing, whether in textiles, furniture, or packaging, lamination processes are critical for enhancing product performance, appearance, and durability. Choosing the right lamination glue is essential to ensure high-quality results. High-performance PUR glue (polyurethane reactive / PUR hot melt glue) offers superior strength, water resistance, and long-term stability, making it increasingly popular in lamination applications across industries.

PUR glue cures through a moisture-driven chemical reaction, forming a dense cross-linked network. Once fully cured, the adhesive is:

Compared with conventional hot melt or solvent-based adhesives, PUR glue provides superior performance in lamination applications.

PUR glue bonds effectively with a variety of substrates, including:

This versatility makes PUR glue an ideal lamination glue for multiple industries.

Modern production lines require adhesives with:

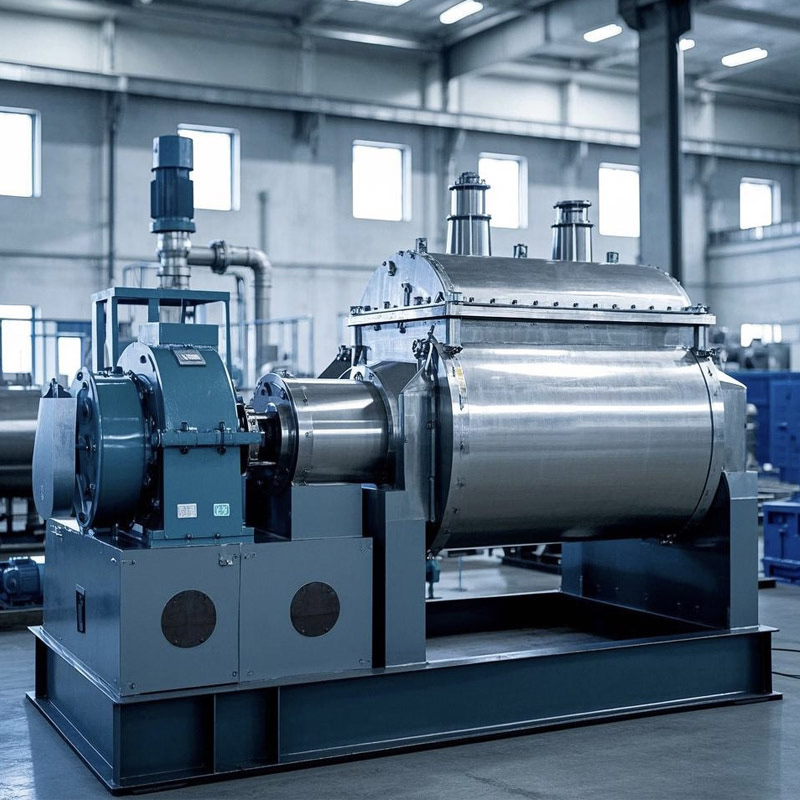

PUR hot melt glue integrates seamlessly with automated lamination equipment, ensuring high efficiency and precision.

Different substrates require different PUR glue formulations to ensure proper wetting, curing, and long-term adhesion.

Control application temperature, open time, and lamination pressure to ensure full moisture-curing and achieve high-strength, water-resistant lamination.

These measures ensure consistent lamination performance across products.

High-performance PUR glue will continue to play a key role in textiles, packaging, furniture, and composite material lamination.

As manufacturers pursue durability, aesthetics, and eco-friendly production, high-performance PUR glue / PUR hot melt glue / polyurethane reactive glue has become a critical material in lamination processes. Selecting the right lamination glue and supplier is essential for ensuring product quality, efficiency, and long-term performance.

Sino Adhesive specializes in PUR glue, PUR hot melt glue, and polyurethane reactive glue systems. Its product portfolio includes high-performance structural PUR glue and moisture-curing PUR glue, widely used in lamination applications across textiles, furniture, packaging, and composite materials.

With professional laboratories and experienced application engineers, Sino Adhesive provides full support from material selection and process optimization to large-scale production, helping manufacturers achieve efficient, reliable, and water-resistant lamination solutions.